Introduction to the Intelligent Autonomous Robot TBOT-500

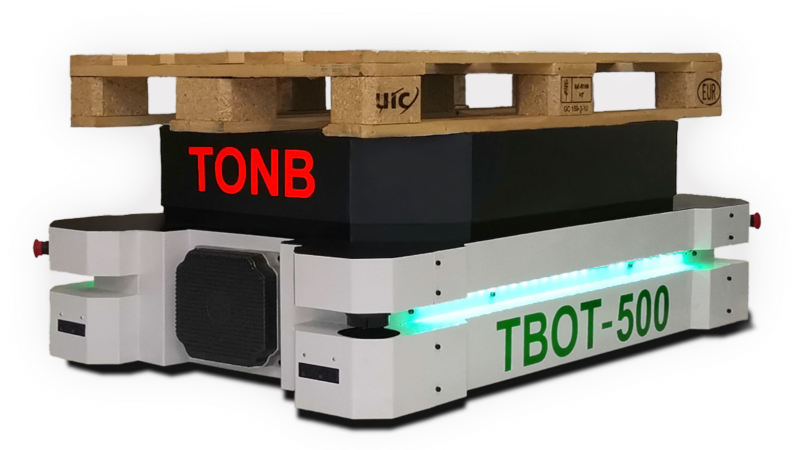

Intelligent Autonomous Robot TBOT-500

The development of intelligent systems, Industry 4.0, and the Internet of Things has created an ideal environment for the use of intelligent robots in various industries. The TBOT-500 intelligent autonomous robot is designed and produced using the latest technology in the robotics industry to enhance process efficiency with minimal environmental changes. This robot belongs to the AMR category, which, unlike AGV types that move on predetermined lines, autonomously determines its path in the environment

The intelligent autonomous Tonb robotic fleet has entered Iran Khodro Company

Pathfinding of the Intelligent Autonomous Robot TBOT-500 in the Presence of Moving Obstacles

Fully autonomous

The TBOT-500 robot maps the environment and navigates without the need for any signs or environmental devices

Seamless integration

Connectable to the Tonb Intelligent Robotic Fleet Management System and other IoT-connected devices

360º view

Laser sensors (Lidar) and a 3D camera give the TBOT-500 a complete view of its surroundings.

500 KG

Utilizing a powerful lifting system, the TBOT-500 is capable of moving pallets weighing up to 500 kilograms.

Up to 8 hours

Using a high-capacity lithium battery, the TBOT-500 robot is capable of carrying loads for up to 8 hours on a single charge

Automatic connection of the TBOT-500 robot to the charging station

Tonb Intelligent Robotic Fleet Management System

With the development of connected systems and Industry 4.0, the use of robots and their interaction with the surrounding environment has grown tremendously. Therefore, the development of control systems for the optimal use of robots in an environment and the management of their communication with each other is essential. The Tonb Intelligent Robotic Fleet Management System is capable of automatically controlling and managing a collection of autonomous robots (especially the TBOT series). This system receives and processes tasks manually (or by connecting to other systems via API). Tasks are processed and then assigned to the most suitable robot based on priority, robot capability, proximity to the load, charge level, and more.

In addition to interacting with the robotic fleet and managing tasks, this system is also connected to other IoT devices (such as doors, conveyor belts, etc.) and coordinates the execution of tasks by the robots with these devices. By collecting information from the robots while moving in the environment and processing it, the paths of the robots are optimized to accomplish more tasks with minimal travel. At the same time, the distribution of robot movements in the environment prevents any traffic and path blockage.

Pathfinding of the Intelligent Autonomous Robot TBOT-500 in the Presence of Fixed Obstacles

Unlimited number of robots

Ability to guide an unlimited number of robots in multiple fleets seamlessly

Control of various types of robots

Connecting various types of robots with different functionalities under one fleet

Smart Task Management

Smart task assignment to robots based on location, traffic, charge, and more.

Cost Reduction

Energy cost reduction by minimizing the distance traveled by robots

Communication with other devices

Ability to communicate with other IoT-connected devices such as doors, lifts, conveyor belts, and more.

Communication with other systems

Receiving tasks via API from other management systems (WMS, ...)

Automatic shelf transport by the intelligent autonomous TBOT-500 robot

Fleet Traffic Management

Fleet traffic management to distribute traffic load on routes and reduce task completion time

Fleet charge management

Assigning tasks based on the robots' charge levels and sending them to the charging station if needed

Win/Android/iOS

Compatible with all kinds of computers, mobile phones, and tablets

Imposing Restrictions

Imposing speed limits, restricted zones, etc., on the fleet in real-time

Real-time fleet monitoring

Viewing fleet status including: robot positions, charge levels, tasks, etc., and remote control of robots

Comprehensive Reporting

Providing various reports to enhance the system and robots' efficiency